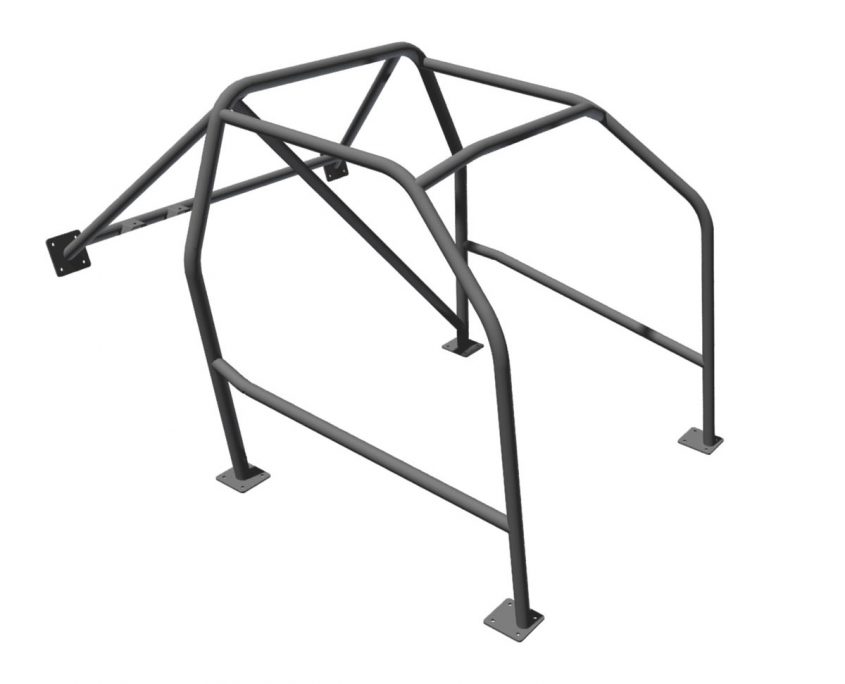

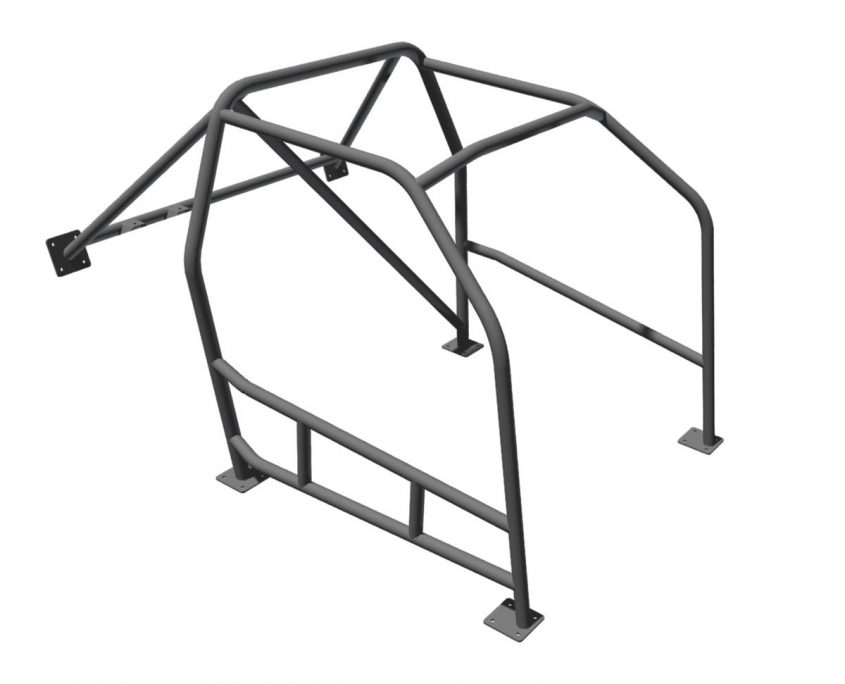

Brown Davis Roll cages

In any form of motorsport where safety is paramount, the single most important aspect of that car’s occupant protection is a properly engineered roll cage. Brown Davis has been engineering CAMS and FIA compliant roll cages (or ROPS – Roll Over Protection Structure) for over 4 decades, including for some of the biggest names and teams in Australian motorsport.

This experience and knowledge of ROPS fabrication has also been called upon for non motorsport specialised projects, including engineering and producing a Roll Over Protection Structure in collaboration with the Ambulance service of Victoria, as well as intricate ROPS designs for mining and military vehicles currently in active service in Afghanistan and Iraq today.